Successful Application Case of Millimeter Wave Radar in Lock Gate Systems

Business Background

On the afternoon of December 9, 2024, at the Minden Lock on Germany's Moselle River, a cargo ship collided with the lock gate due to excessive speed and proximity, severely damaging two gates and hydraulic systems. The repair took nearly three months, incurring losses of 500,000 euros.

On November 13, 2022, at the Wuzhou Changzhou Lock in Guangxi, low traffic efficiency caused severe congestion, stranding nearly 1,500 vessels with an average delay of seven days.

(Images sourced from the internet; please contact for removal if copyrighted.)

Policy Guidance

China’s Guidance on the Development of Intelligent Shipping outlines phased goals (basic infrastructure by 2025, full intelligence by 2035, and a high-quality system by 2050) to drive the industry toward automation and intelligence. Millimeter-wave radar and other smart sensors are becoming indispensable for safe and efficient lock operations.

Core Challenges in Lock Operations

Severe Vessel Congestion: China’s inland waterway freight volume exceeds 6 billion tons annually, straining locks with high-density traffic and necessitating efficiency improvements.

Escalating Entrapment Risks: Large-tonnage vessels risk damaging lock structures (repairs costing nearly millions), blocking waterways, or causing casualties. Precise vessel positioning and predictive technologies are urgently needed to adjust gate operations.

Inefficient Manual Inspections: Current gate controls rely on manual checks, which are hindered by weather, nighttime visibility, and human factors, demanding smart detection systems to replace labor.

Market Solution Comparison

Common anti-entrapment and traffic efficiency solutions: visual cameras, infrared beams, LiDAR, etc.

| Technical Metrics | MMW Radar + Vision | Vision Only | Infrared Beams | LiDAR |

| Detection Range | Medium-long (10–300 m); Multi-angle installation (up to 90° pitch) | Mostly no ranging; High algorithm dependency (costly) | Short-range (≤50 m) | Medium-long (50–300 m) |

| Ranging Accuracy | High (±0.5 m) | Image-based, large errors | Presence detection only | Ultra-high (±2 cm) |

| Reliability | All-weather (penetrates rain/fog/dust) | Weather/light/smoke-sensitive | Weather/light/smoke-sensitive | Weather/light/smoke-sensitive |

| Cost | Medium | Low | Low | High |

Considering performance, reliability, and cost, MMW radar + vision offers the best cost-efficiency.

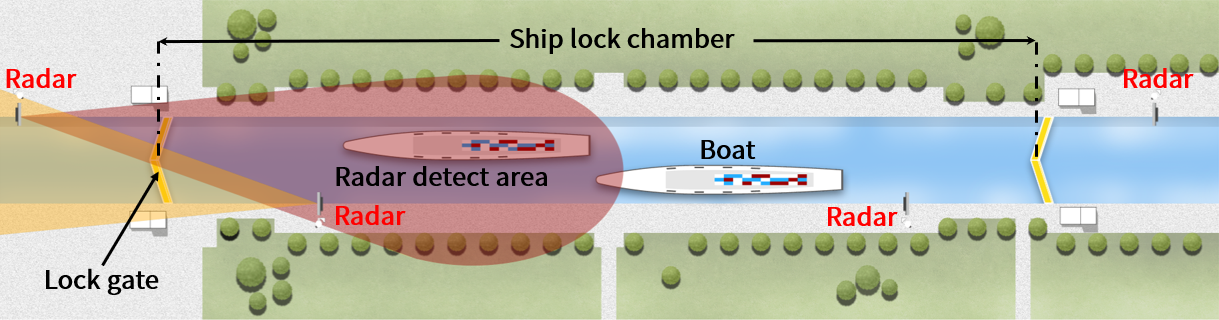

MMW Radar-Based System Solution

System Architecture

Core Functions:

Detects inbound vessels in the lock chamber; triggers PLC-controlled gate closure at preset distances.

Monitors approaching vessels outside the lock for distance/speed to assess collision risks and halt gate closure if needed.

Ground Surveillance Radar NSR100W

| Parameter | Specification |

| Frequency Band | 24~24.25GHz (Approved in China, US, EU) |

| Angular Coverage | Azimuth: 90° Elevation: 13° |

| Detection Range (Ship) | 300m |

| Ranging Accuracy | ±0.5m |

| Distance Resolution | 1m |

| Speed Range | 0.5~30m/s |

| Speed Accuracy | 0.03m/s |

| Speed Resolution | 0.06m/s |

| Communication Interface | RJ45 10M/100M (PoE)/RS485/Modbus |

| Protection Rating | IP66 |

On-Site Deployment

Equipment: 4 MMW radars (single waterway), 4 PTZ cameras, 1 server, 2 gate controllers.

Radar Installation

Method 1: For locks with upstream/downstream water level differences <10 m, front-mounted radars ensure effective vessel detection.

Method 2: For differences >10 m, side-mounted radars adjust vertical detection to 90° for multi-level coverage.

Customer Benefits

70% reduction in gate collisions/entrapments, saving >8 million CNY in repairs.

25% higher traffic efficiency: Average transit time shortened from 40 to 30 minutes.

50% fewer manual inspections, cutting O&M costs by 20%.

RELATED PRODUCTS

Ground Surveillance Radar NSR100W