3D Millimeter Wave Radar Helps State Grid Prevent External Damage in Transmission Corridors

"Extensive operational statistics show that external damage incidents to transmission lines have become a major threat to the reliability and safety of the power grid. With the growth of economic and infrastructure development, construction activities involving large special vehicles—such as cranes, pump trucks, excavators, and pipe jacking machines—near or beneath transmission corridors are becoming increasingly frequent. A single oversight can lead to external damage incidents. In 2015, a region in Jiangsu experienced over a dozen such incidents caused by crane and pipe jacking operations."

—A power grid company in Jiangsu

Business Challenges

Traditional anti-external damage technologies have proven ineffective and economically inefficient, making transmission corridor protection a persistent challenge for power line safety. There is an urgent need for technological innovations in detection capabilities, application strategies, and management models to enhance the precision, timeliness, and effectiveness of monitoring construction machinery hazards. This will fundamentally eliminate potential risks and ensure the safe operation of transmission lines.

Current Market Solutions: 3D Radar + Fixed Cameras Show Significant Advantages

Feature | Legacy Laser + PTZ Camera System | 3D Radar + Fixed Camera System |

Monitoring | Requires real-time surveillance | View footage only upon alerts |

Timeliness | Post-incident review | Early warning with lead time |

Interaction | None | On-site alarms and voice alerts to warn operators |

Detection Capability | Laser: Single-line scanning, prone to malfunctions and environmental interference | Radar: Area detection, wider coverage, immune to environmental interference |

Radar-Based Solution

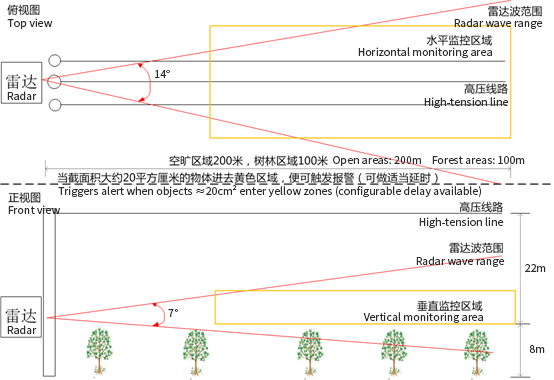

3D Radar Coverage: Customizable monitoring zones

On-Site Power Supply

Three 100W monocrystalline solar panels power the tower-mounted equipment, including image recognition, audible/visual alarms, microphones, and 4G communication devices, ensuring 24/7 operation.

Two 100AH batteries provide backup power for nighttime operation.

On-Site Equipment

2MP digital camera × 1, 4G router × 1, Height-measuring radar (Nanoradar) × 1, Audible/visual alarm system × 1, Audio amplification system

4G Mobile Communication

On-site terminals connect to a central Linux server via 4G, requiring a fixed IP address to maintain uninterrupted communication, even after power outages.

Customer Benefits

Real-Time Monitoring and Alerts: Vehicle-mounted devices enable multi-party (operators, supervisors) proactive warnings, reducing risky behaviors and enhancing detection of hazardous construction activities.

Integrated Monitoring and Patrols: Combines manual inspections with real-time technological monitoring, leveraging the strengths of both—adaptive patrol strategies and continuous, quantitative data—to address staffing shortages and enable early detection and control of threats.

Enhanced Hazard Identification: Intelligent recognition of cranes, pump trucks, excavators, and pipe jacking machines improves proactive safety management, reducing blind spots and uncontrollable risks from mobile construction machinery.

RELATED PRODUCTS

Ground Surveillance Radar NSR100W