——Jiangsu Power Grid

Nanoradar’s SPC865 4D Radar for Transmission Line Foreign Object Prevention is now launched.

How does millimeter-wave radar technology become a game-changer for real-world transmission line protection?

Traditional anti-third-party damage measures are limited in effectiveness, making transmission corridor protection a persistent challenge. Innovative technical solutions are needed to enhance the precision, timeliness, and targeting of construction machinery monitoring, ensuring transmission line safety.

II. Millimeter-Wave Radar Solution: True Radar-Vision Fusion

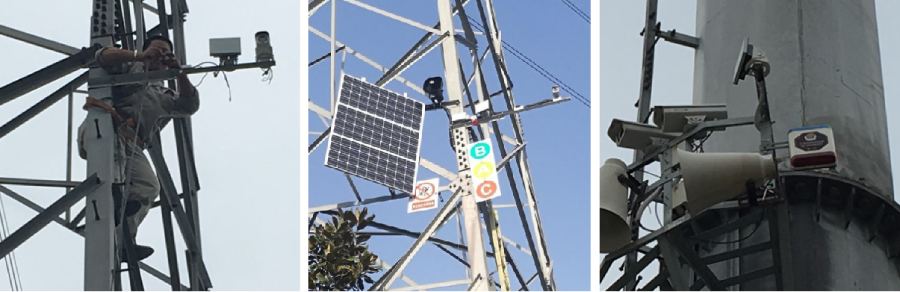

Radar Ranging

Uses 4D millimeter-wave radar to monitor hazards within an 800m (length) × 80m (width) zone below multi-bundle conductors, operating 24/7.Radar-Vision Fusion

Breakthroughs in feature registration and AI-powered distance measurement cluster radar-detected points, fuse visual bounding boxes, and calculate hazard distances via coordinate conversion—fully realizing radar-vision fusion for transmission line protection.

III. SPC865 Radar: The "Recon Scout" for Transmission Lines

The SPC865 acts as a 24/7 sentry, detecting hazards in real time—undeterred by darkness or harsh weather. Its 800m × 80m coverage below conductors ensures proactive grid safety.

IV. Field Validation: From Reactive to Proactive Defense

●Real-time alerts via vehicle-mounted devices warn both operators and supervisors, reducing risky behavior through technical + managerial safeguards.

●Integrated monitoring combines AI-driven radar with manual patrols, leveraging continuous data and human expertise to detect and mitigate threats early—critical for high-risk machinery (cranes, excavators, etc.).

●Smart recognition of cranes, pump trucks, and drilling rigs empowers inspectors, minimizing mobile equipment hazards.